Medical Simulation for Surgical Training in Virtual Environments

Simulation-based training using VR techniques is a promising alternative to traditional training in minimally invasive surgery (MIS). Simulators let the trainee touch, feel, and manipulate virtual tissues and organs through the same surgical tool handles used in actual MIS while viewing images of tool-tissue interactions on a monitor as in real laparoscopic procedures. Developing a VR-based MIS Simulator requires expertise in systems engineering, materials engineering, robotics engineering, computer science, biomedical engineering, and medicine. The development of a surgical simulator typically involves five major steps; first, the developers use segmentation and reconstruction techniques of computer vision and computer graphics to generate 3D anatomical models of organs from medical images. Second, they measure and characterize the material properties of soft tissues and integrate these properties in organ-force models. Next, they develop collision detection and response techniques to simulate the real-time interactions of simulated surgical instruments and manipulated organs. Then, they integrate the simulator’s hardware and software components to form a complete system. Finally, they validate the system and measure training transfer through user studies. In our laboratory, we conduct research and development for each of these steps.

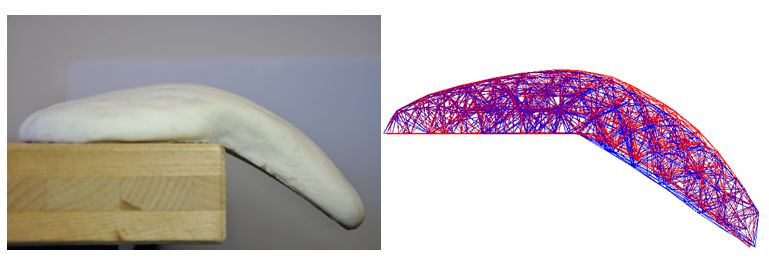

Force-Based Calibration of a Particle System for Realistic Simulation of Nonlinear and Viscoelastic Soft Tissue Behavior

We present a new approach for realistic visio-haptic simulation of nonlinear and viscoelastic behavior of an organ tissue using a particle model. The spring and damper coefficients of the particle model are calibrated using a derivative-free optimization technique such that its behavior mimics the behavior of a corresponding finite element (FE) model. In our approach, we first conduct static indentation and stress relaxation experiments on the FE model to record a) force versus displacement and b) force versus time responses of the surface nodes, respectively. We then use these data sets to calibrate the spring and damper coefficients of the particle model such that its force response is similar to that of the FE model. To test the feasibility of our approach, we compare the static and dynamic behavior of the particle model to that of the FE model under the influence of gravity.

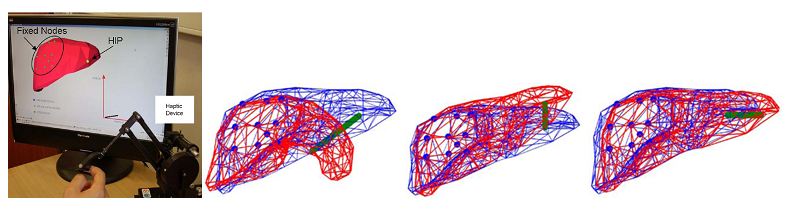

Real-time Visio-Haptic Interaction with Static Soft Tissue Models Having Geometric and Material Nonlinearity

Realistic soft tissue models running in real-time are required for the development of computer-based surgical training systems. To construct a realistic soft tissue model, finite element (FE) modeling techniques are preferred over the particle-based techniques since the material properties can be integrated directly into the FE model to provide more accurate visual and haptic feedback to a user during the simulations. However, running even a static (time-independent) nonlinear FE model in real- time is a highly challenging task because the resulting stiffness matrix (K) is not constant and varies with the depth of penetration into the model. We propose a new computational approach allowing visio-haptic interaction with an FE model of a human liver having both nonlinear geometric and material properties. Our computational approach consists of two main steps: a pre-computation of the configuration space of all deformation configurations of the model, followed by the interpolation of the precomputed data for the calculation of the nodal displacements and reaction forces that are displayed to the user during the real-time interactions through a visual display and a haptic device, respectively.

Real-Time Finite-Element Simulation of Linear Viscoelastic Tissue Behavior Based on Experimental Data

We propose an end-to-end solution to real-time and realistic finite-element modeling and simulation of viscoelastic soft tissue behavior. We provide an efficient numerical scheme for solving a linear viscoelastic FEM model derived from the generalized Maxwell solid, and present methods for measuring and integrating experimental data on the viscoelastic material properties of soft tissues into the model for realistic display of visual deformations and interaction forces. Our precomputation scheme and multilayer computational architecture enable the model’s real-time execution with visual and haptic feedback to the user. Researchers have applied the precomputation approach to real-time static FEM simulation in the past, but, to our knowledge, no one has extended it to the real-time linear viscoelastic FEM simulation. Our approach includes time and rate dependent effects, which requires considering a node’s loading history in our displacement computations at each cycle of the simulation.

Graphical and Haptic Simulation of Laparoscopic Common Bile Duct Exploration

We have developed a computer-based training system to simulate laparoscopic procedures in virtual environments (VEs) for medical training. The major hardware components of our system include a computer monitor to display visual interactions between three–dimensional (3-D) virtual models of organs and instruments together with a pair of force feedback devices interfaced with laparoscopic instruments to simulate haptic interactions. In order to demonstrate the practical utility of the training system, we have chosen to simulate a surgical procedure that involves inserting a catheter into the cystic duct using a pair of laparoscopic forceps. This procedure is performed during laparoscopic cholecystectomy (gallbladder removal) to search for gallstones in the common bile duct. Using the proposed system, the user can be trained to grasp and insert a flexible and freely moving catheter into the deformable cystic duct in virtual environments. As the catheter and the duct are manipulated via simulated laparoscopic forceps, the associated deformations are displayed on the computer screen and the reaction forces are fed back to the user through the force feedback devices.